Recently, the technical team of?HV HIPOT was invited to the Foxconn Park in Henan Province to have in-depth exchanges on the application and optimization of partial discharge inspection instruments, building an efficient communication bridge for the subsequent technical cooperation and equipment services between the two sides.

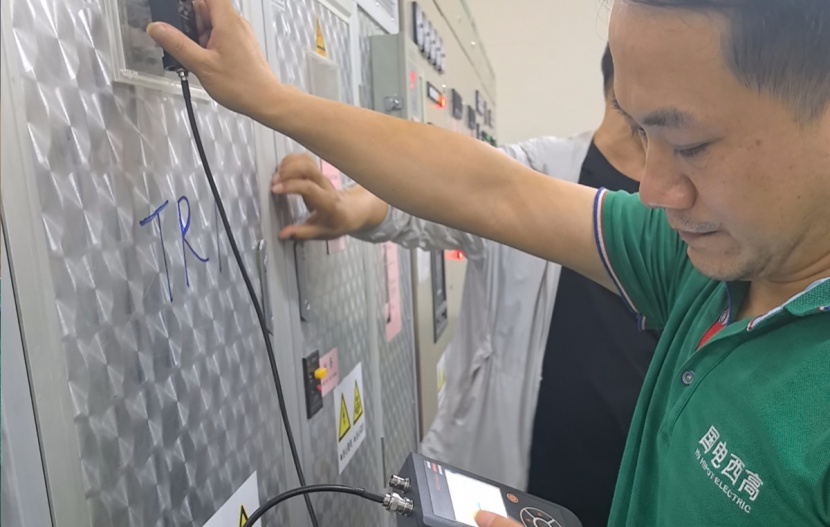

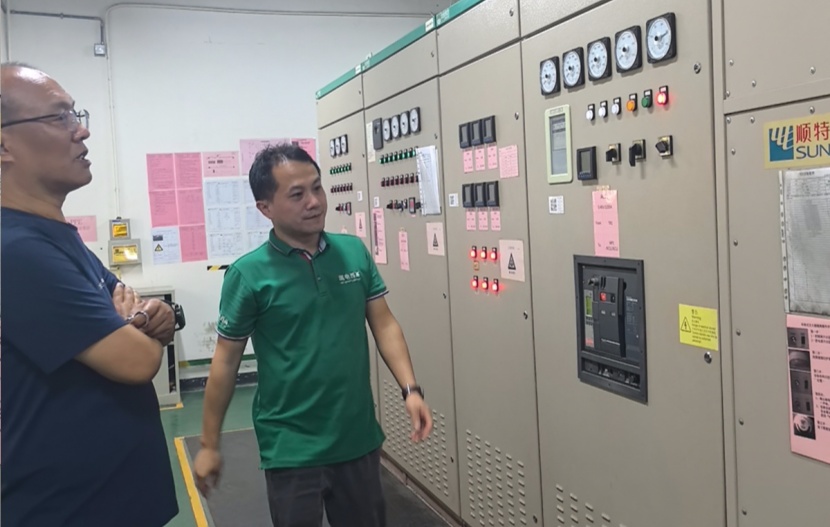

During the communication, the team from HV HIPOT, taking into account the operational characteristics of the power equipment in Foxconn’s production workshop, elaborately introduced the core technical advantages of the partial discharge inspection instrument. The high-precision sensor module it is equipped with can accurately capture the early discharge signals of the equipment. Coupled with the intelligent data analysis system, it can achieve early warning and location of potential faults, effectively reducing the risk of production line shutdowns caused by power failures. In response to Foxconn’s practical demands such as equipment compatibility and detection efficiency, the technicians on site demonstrated the operation process of the instrument and provided one-on-one answers to questions regarding parameter adjustment and daily maintenance, which were highly recognized by the technical person in charge of the other party.

As a globally significant smart manufacturing base, Foxconn in Henan Province has extremely high requirements for the stability of power equipment. This exchange not only made the technical solutions of?HV HIPOT more in line with the actual scenarios of the enterprise, but also laid the foundation for both sides to explore cooperation in power safety in the field of smart manufacturing. In the future,?HV HIPOT will continue to be driven by technological innovation and provide more customized power detection solutions for enterprises.

Post time: Oct-25-2025